Smart Storage Engineering: The Role of Cantilever Racking in Modern Warehousing

In today’s fast-moving logistics landscape, warehouse technology is about more than just robotics and automation. The foundation of a high-performing supply chain often lies in how efficiently materials are stored and accessed. This is where cantilever racking comes in—a storage technology designed for flexibility, scalability, and strength.

Engineered with advanced structural design principles and supported by compliance with FEM and Australian standards, cantilever systems are a key part of modern industrial technology infrastructure.

The Technology Behind Cantilever Racking

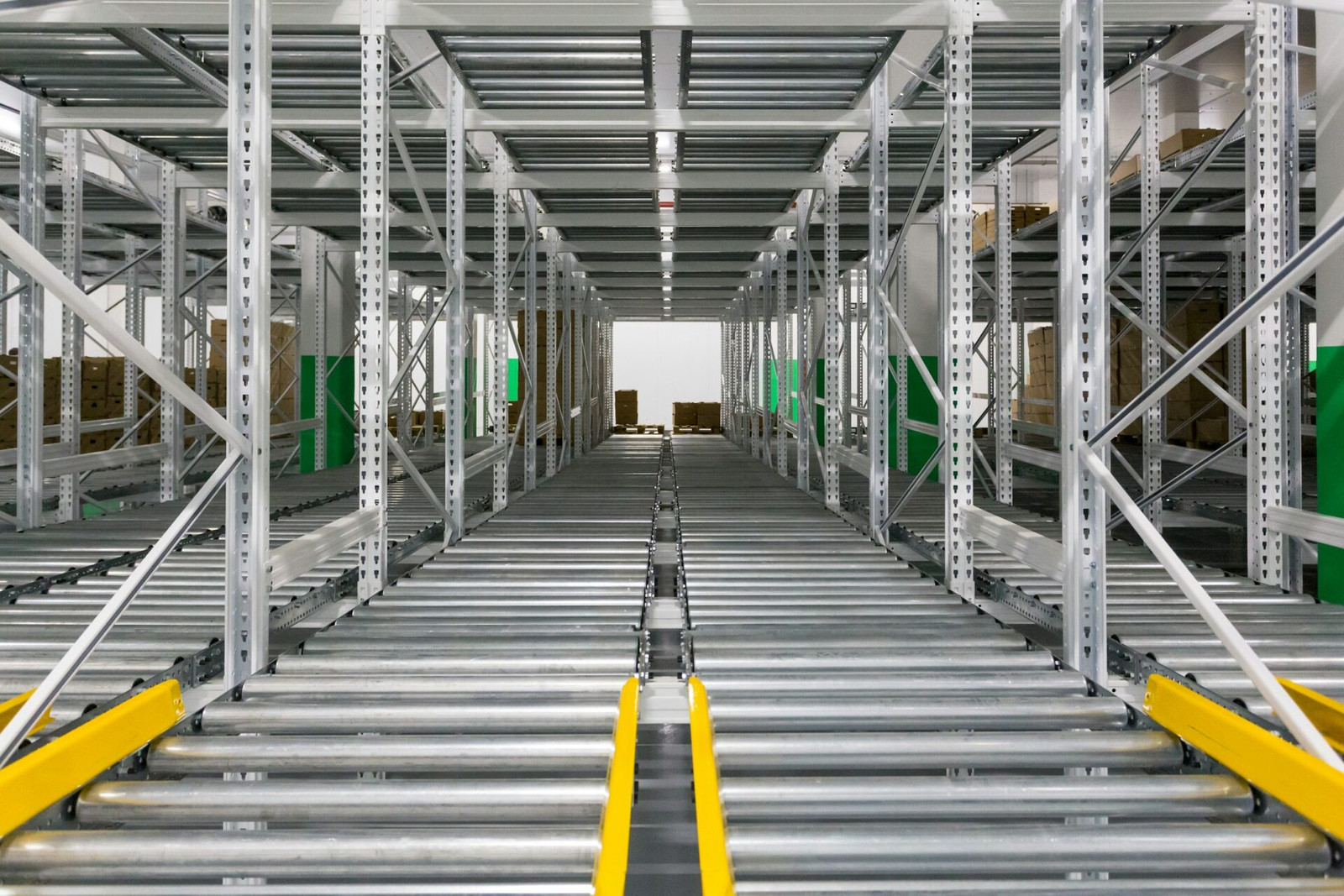

At its core, cantilever racking replaces traditional fixed-beam shelving with uprights and extendable arms. While the concept seems simple, the technology is rooted in precision engineering. The open-frame design allows AI-assisted forklifts and automated guided vehicles (AGVs) to seamlessly load and unload long or irregularly shaped items—like steel beams, timber, pipes, or sheet materials—without obstruction.

This structural technology enables:

- Dynamic adaptability – adjustable arms and heights ensure compatibility with diverse loads.

- Enhanced accessibility – automation systems can quickly locate and retrieve items thanks to the obstruction-free design.

- Cross-industry use – from construction materials to aerospace components, cantilever systems can be deployed indoors or outdoors with powder-coated or galvanised finishes.

Scaling Storage with Technology: Light to Heavy Duty

Not all warehouses face the same demands. That’s why cantilever systems are designed with different load capacities, offering a modular and scalable approach to storage technology:

- Light-duty systems – for hand-loaded operations where precision matters, like handling aluminium sheets or smaller timber lengths.

- Medium-duty systems – able to hold up to 1,000 kg per arm, supporting bulky items like plasterboard, rolls, or furniture.

- Heavy duty cantilever racking – engineered for extreme loads, handling several tonnes per upright, ideal for automated warehouses storing steel, large timber, or industrial machinery parts.

Integration with Smart Warehousing

As warehouses become more digitised, cantilever systems integrate seamlessly with Warehouse Management Systems (WMS), IoT-enabled monitoring, and even robotics. Sensors can track load capacity, structural strain, and environmental conditions, ensuring predictive maintenance and safety.

For example:

- IoT integration allows managers to monitor stress points in heavy duty cantilever racking, ensuring early intervention before structural fatigue.

- Automation-ready design makes it easier for robotic forklifts to navigate, reducing human error and improving throughput.

- Data-driven optimisation ensures warehouse layouts maximise storage density while keeping retrieval times low.

Why Cantilever Racking Sets the Standard in Industrial Tech

- Customisable engineering – modular designs can be adapted to the digital twin models used in warehouse simulations.

- Future-ready durability – galvanised finishes and certified engineering make them compatible with outdoor, high-demand environments, including cyclone zones.

- Reliability at scale – structural warranties combined with compliance frameworks mean businesses can safely scale operations without compromising on safety.

The Future of Storage Technology

As industries adopt smart factories and Industry 4.0 principles, the role of storage technology becomes increasingly critical. Cantilever racking, especially in its heavy duty cantilever racking form, bridges traditional material handling with digital warehouse transformation. By combining robust engineering with smart integration, these systems enable warehouses to keep pace with automation, AI, and predictive logistics.

Similar Posts

Understanding the Phone Number 0394926347

Journey of Virtual Reality in the Health Sector

Samsung’s Tiny AI Model Challenges DeepSeek and Gemini on Reasoning | Is It True?